When you think about cardboard boxes, you might imagine their sturdy exterior, but peel back a layer, and you’ll discover the unsung hero of their strength and durability—flutes. If your business depends a lot on cardboard boxes, you’ll want to know what flutes are in a cardboard box and why they’re important. These seemingly simple ridges on the inside of corrugated cardboard are responsible for much of the box’s functionality.

Flutes are not just a random design choice; they are foundational to the structure, performance, and overall reliability of cardboard boxes. Whether you’re in the packaging industry or simply curious about what makes these boxes so effective, understanding flutes will give you a new appreciation for their role.

Flutes Explained

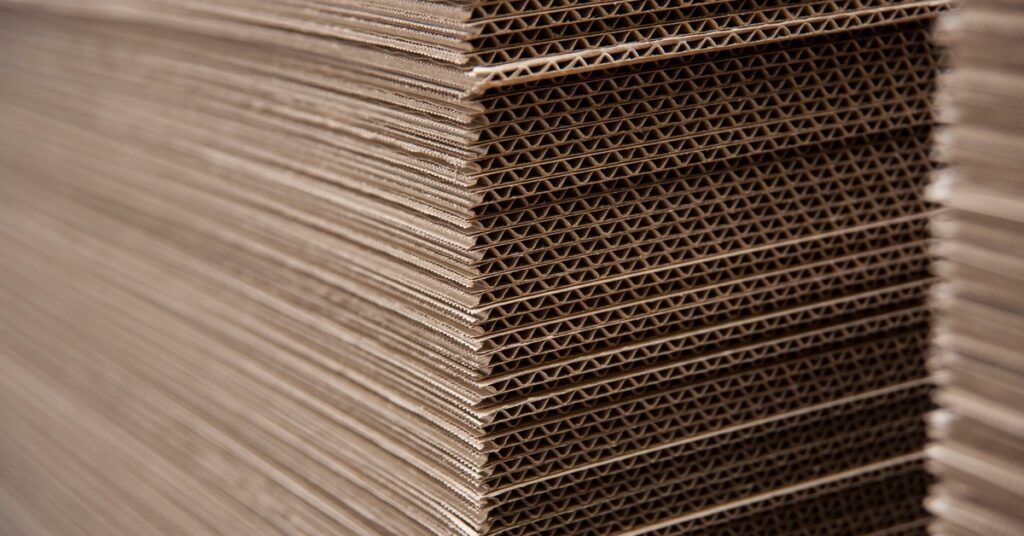

Flutes are the wavy, arch-like ridges sandwiched between two flat layers of paper in corrugated cardboard. These ridges are more than just a decorative pattern. Their shape and placement enhance the strength, flexibility, and resistance of a cardboard box, making it a high-performing packaging material.

Think of flutes as the backbone of corrugated cardboard. They distribute weight while also providing cushioning, key attributes that make cardboard boxes the go-to solution for countless industries. The arches create tiny columns within the box structure, enabling it to withstand pressure and resist crushing.

The utility of the design has its roots in architectural principles that people have used for centuries, proving once again that the simplest ideas often have the greatest impact. If you’re shipping fragile glassware or bulky industrial parts, the flutes in your cardboard box will offer consistent protection.

Types of Flutes and Their Uses

Flutes come in various sizes, shapes, and configurations, each created for specific uses. The height and number of ridges per linear foot classifies these variations. Larger flutes provide higher cushioning, while smaller ones offer better flexibility and printability. Selecting the right flute type can have a direct impact on product safety, shipping costs, and even branding efforts.

One of the most common types is the “A-flute,” prized for its thick structure and superior cushioning properties. It performs incredibly well when handling fragile items that need extra protection during transport.

Meanwhile, the “B-flute” is thinner but offers remarkable puncture resistance. This flatter, sturdier structure makes it an ideal choice for smaller, heavier products where durability is a priority over cushioning.

There’s also the popular “C-flute,” which strikes a balance between strength and cushioning. Its versatility enables it to handle everyday goods consistently, making it the go-to option in most general use cases.

On the other hand, “E-flute” is much finer in profile and delivers excellent printability for branding, making it popular for retail packaging. Finally, the “F-flute” is ultra-thin, making it perfect for lightweight packaging that still requires structural integrity.

Importance in Packaging

Knowing the role of flutes helps highlight why cardboard boxes remain indispensable in modern commerce. Flutes enhance the boxes’ load-bearing capacity.

By supporting weight evenly, they allow the boxes to stack efficiently during storage and transport without collapsing. This capability isn’t just handy; it’s critical for industries where reducing storage space translates into direct cost savings.

Equally important is the cushioning provided by these ridges. They absorb shocks and vibrations, protecting products from damage during shipment. Flutes create a built-in buffer that reduces the impact of sudden jolts, a feature that’s particularly necessary for fragile or high-value items.

Flutes also play a fundamental role in sustainability. Typically, the corrugated layers use recycled paper, and their strength allows for repeated reuse and recycling. This eco-friendly design reduces waste, lowers energy consumption, and aligns with growing consumer demand for greener packaging options.

Whether the priority is protection, branding, lightweight solutions, or cost efficiency, you can find flute types that match your needs. This adaptability is especially useful in industries such as food manufacturing, where packaging often serves as a marketing tool.

Real World Applications

The practicality of fluted boxes becomes clear when you see them in action. Consider the electronics industry, which requires multi-layered protection for sensitive gadgets. Flutes provide the necessary cushioning and climate resistance to make sure devices arrive undamaged, whether traveling across the country or around the globe.

The food industry provides another example of why flutes matter. Take pizza packaging, for instance. E-flutes allow boxes to be robust enough to carry hot, greasy pizza while staying lightweight for easy transport. This design effectively balances strength, heat retention, and efficient material usage.

Even in the automotive sector, flutes play an integral role. Packaging solutions must be capable of handling heavy parts without adding unnecessary weight to shipping costs. That’s where larger flutes, such as A- or C-flutes, provide the toughness to protect against rough handling while still keeping packaging cheaper.

Why You Should Care

If you’re in the business of shipping products, the fluting in your cardboard boxes can make a big difference in cost and customer fulfillment. Using the wrong type could lead to damaged goods, increased return rates, and a damaged brand image. On the flip side, selecting the right fluting can provide significant benefits, from reducing breakage rates to improving the customer’s unboxing experience.

For industrial clients, these benefits rise significantly. Stronger boxes mean fewer replacements and lower overall shipping expenses. They also contribute to sustainability goals by reducing material waste and resource consumption. It’s a win for the bottom line and the environment.

Even beyond business considerations, understanding the correct uses of flutes helps consumers make informed choices. When buying furniture, appliances, or even subscription boxes, knowing the complexity of packaging highlights the value of choosing well-protected goods. The confidence that your order will arrive intact doesn’t come by chance; it’s the flutes working behind the scenes.

Looking Ahead

The future of packaging is closely tied to advancements in flute design and materials. With many industries moving toward smarter, greener, and more streamlined solutions, flutes will continue to develop.

For instance, micro-fluting technologies promise even thinner, lighter packaging that doesn’t sacrifice performance. Combined with recyclable materials and improved moisture resistance, these advancements could redefine packaging in ways we’ve yet to imagine.

The global expansion of e-commerce will continue to drive the need for versatile box designs. With growing consumer demand for fast and safe delivery, flutes will play an even larger role in shaping the shipping experience. Companies that prioritize high-quality flute options from a corrugated box supplier in their packaging will likely dominate in the increasingly competitive landscape.

The Next Steps

What flutes are in a cardboard box and why they’re important might seem like a small detail, but they are the heroes behind the sturdiness, flexibility, and performance that make these boxes indispensable. From protecting fragile items to boosting efficient stacking, their contributions ripple through industries, guaranteeing goods arrive safely.

Contact United Container for assistance in selecting the right flute type for your business. Perfecting your packaging potential will lower waste and reduce costs. By appreciating the role flutes play in your business operations, you’re able to use their power to upgrade your packing and shipping process.

Posted by